With more than 60 years of experience in the field of intralogistics, we have the necessary knowledge to develop the best solutions for our customers. Well thought-out planning is the basis of efficient transport and warehouse logistics – a challenge that today helps decide a company’s productivity and competitiveness.

As part of the SMS group, AMOVA has access to the group’s own workshops in Germany, India, China, the USA and Brazil as well as a global network of certified production companies. AMOVA has been certified as complying with all the important standards: DIN EN ISO 9001, DIN EN ISO 14001, DIN EN ISO 50001, BS OHSAS 18001 and EN 1090-1. We therefore guarantee the highest quality and reliability.

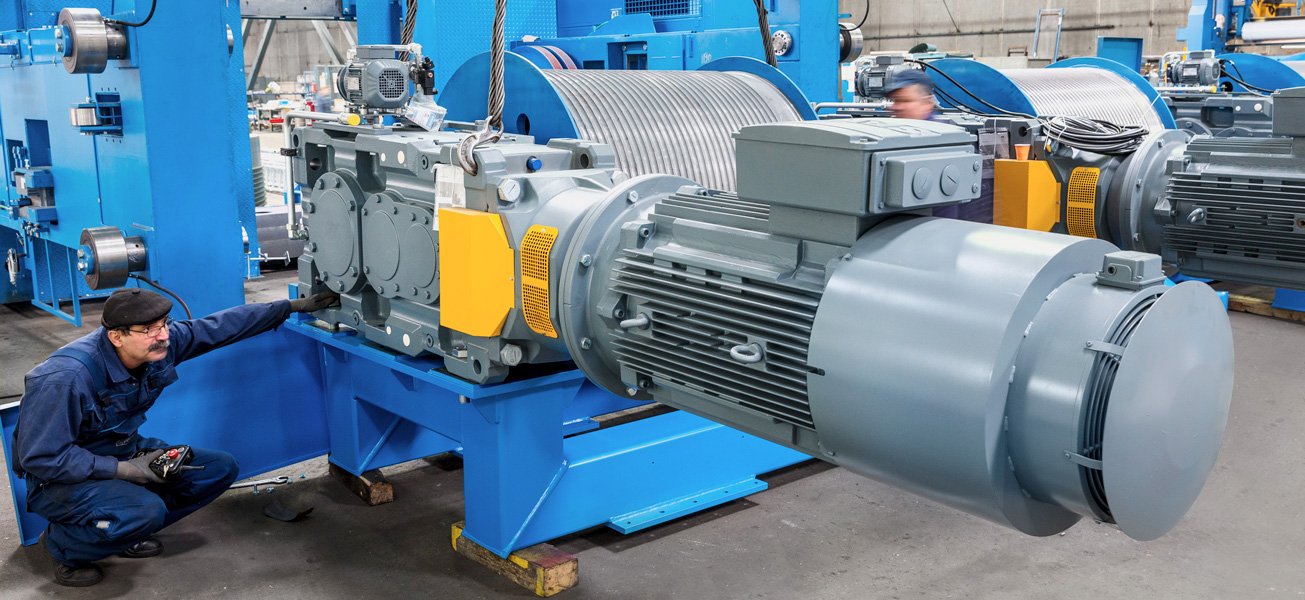

We assemble, install and commission – all over the world. Many technical and logistical challenges arise during the assembly and commissioning of plants, whether in steel or aluminium works, in air-cargo terminals or in container ports. Work is often carried out in or on existing plants when existing systems are being extended or converted. We plan our work very carefully in advance and, if necessary, draw up with you a concept for the process and site logistics so that ongoing operations are impaired as little as possible. Safety comes first with us, of course – naturally, we are SCC-certified. Our experienced site managers will also be happy to help you train your personnel efficiently in handling the new plant.

We achieve a fast system run-up by intensive software testing. In the development phase the logistics system is simulated virtually. That way all the work processes and procedures can be run through in advance and faults rectified.

AMOVA not only supplies new systems, we also support you in modernizing and overhauling your plants. We work with you to develop suitable concepts for increasing the performance of your existing systems and their availability. Up-to-the-minute automation and IT systems open up to your system new functionalities and guarantee the supply of spare parts and support. Our solution specifies how the planned modernization or extension can be technically and economically realized to the highest possible standard. Special attention is paid to the changeover scenario to avoid disrupting your work processes and procedures.

So you are not only planning and building a new intralogistics concept in your plant, but would also like to place the subsequent maintenance and repair in reliable hands? No problem. We would be pleased to offer you a service model where, as a service provider, we assume responsibility for the servicing and maintenance of the entire system.